VW Golf (1K) Brake Electronics (MK60EC1)

Coding

Coding for this Control Module is normally done via Software Version Management (SVM). If the old Control Module is still accessible read/copy its Coding and Paste it into the New coding line of the replacement Module.

- If the old control module will not communicate, or the original coding was not saved prior to repairs, registered customers can contact us directly via email for assistance. Please send the complete Auto-Scan with the recent repair history and we can try to help with the Coding Process.

- It is strongly recommended to complete the Sensor for Steering Angle (G85) Basic Setting operation immediately after coding the control module.

Security Access

VCDS will provide this Information specific to the Control Module once you open the Security Access Function.

Basic Setting

Sensor for Steering Angle (G85)

Prerequisites:

- Start the vehicle.

- Turn the steering wheel one turn to the right and one turn to the left.

- Drive in a short distance straight line on a level surface at a speed not higher than 20 km/h.

- If the steering wheel is straight during the test drive then stop the vehicle with the wheels pointed straight.

- Ensure that the steering wheel is not moved again.

- Keep the engine running and do not switch off the ignition.

- System voltage at least 12.0 V.

[Select]

[03 - Brake Electronics]

[Measuring Blocks - 08]

Group 004

[Go!]

Check field 1, the value has to be between -1.5 and +1.5 °.

[Done, Go Back]

[Security Access - 16]

Enter 40168, to enable the basic setting.

[Do it!]

[Basic Settings - 04]

Group 060

[Go!]

After a successful basic setting, field 2 should say "OK".

[Done, Go Back]

[Close Controller, Go Back - 06]

Note:

- If Adjustment Not Possible is displayed:

- The On/Off/Next button was used and the procedure will need to be repeated WITHOUT clicking it.

- The G85 live values were not within the +/-1.5 °specification. Repeating the procedure within specifications should resolve it.

- The Steering wheel should be turned to full right lock stop and to full left lock stop and centered again followed by repeating the procedure.

- The 16-Steerign Wheel control module and 44-Steering Assist control module (when applicable) Coding and Adaptation configurations should be checked to rule out a conflict.

- After successful basic setting, the Steering Limit Stop needs to be adapted too.

Lateral Acceleration Sensor (G200)

Prerequisites:

- System voltage at least 12.0 V.

[Select]

[03 - Brake Electronics]

[Measuring Blocks - 08]

Group 004

[Go!]

Check field 2, the value has to be between -1.5 and +1.5 m/s².

[Done, Go Back]

[Security Access - 16]

Enter 40168, to enable the basic setting.

[Do it!]

[Basic Settings - 04]

Group 063

[Go!]

After a successful basic setting, field 2 should say "OK".

[Done, Go Back]

To make sure the basic setting was successful, check the sensor again.

[Measuring Blocks - 08]

Group 004

[Go!]

Check field 2, the value has to be between -1.5 and +1.5 m/s².

[Done, Go Back]

[Close Controller, Go Back - 06]

Brake Pressure Sensor 1 (G201)

Prerequisites:

- System voltage at least 12.0 V.

[Select]

[03 - Brake Electronics]

[Measuring Blocks - 08]

Group 005

[Go!]

Check field 1, the value has to be between -8.0 and +8.0 bar.

[Done, Go Back]

[Security Access - 16]

Enter 40168, to enable the basic setting.

[Do it!]

[Basic Settings - 04]

Group 066

[Go!]

After a successful basic setting, field 2 should say "OK".

[Done, Go Back]

To make sure the basic setting was successful, check the sensor again.

[Measuring Blocks - 08]

Group 005

[Go!]

Check field 1, the value has to be between -3.8 and +3.8 bar.

[Done, Go Back]

[Close Controller, Go Back - 06]

Longitudinal Acceleration Sensor (G251)

Note:

- The Longitudinal Acceleration Sensor (G251) is only present cars with All Wheel Drive (AWD) and/or Hill Hold Control (HHC)

Prerequisites:

- System voltage at least 12.0 V.

[Select]

[03 - Brake Electronics]

[Measuring Blocks - 08]

Group 006

[Go!]

Check field 4, the value has to be between -1.5 and +1.5 m/s².

[Done, Go Back]

[Security Access - 16]

Enter 40168, to enable the basic setting.

[Do it!]

[Basic Settings - 04]

Group 069

[Go!]

After a successful basic setting, field 2 should say "OK".

[Done, Go Back]

To make sure the basic setting was successful, check the sensor again.

[Measuring Blocks - 08]

Group 006

[Go!]

Check field 1, the value has to be between -1.5 and +1.5 m/s².

[Done, Go Back]

[Close Controller, Go Back - 06]

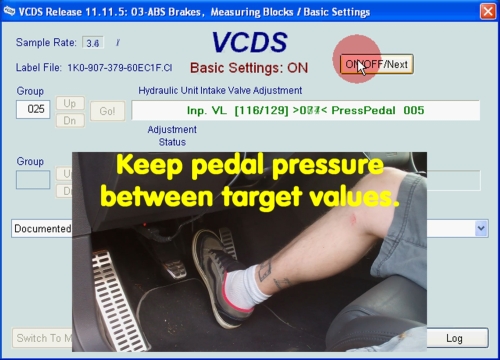

Basic Setting for Hydraulic Unit Intake Valves

The Basic Setting procedure for the Intake and Disconnect valves is only to be done when the ABS module is replaced and fault code 00003 - Control Module: No or Incorrect Basic Setting / Adaptation is present.

Prerequisites:

- The pump temp must be below 27°C / 80°F. It may be necessary to use a fan with the hood open to keep the temp. down.

- The engine should be running due to the high brake fluid pressures required to complete the test.

Note: Both the Basic Setting for Hydraulic Unit Intake Valves and Basic Setting for Hydraulic Unit Disconnecting Valves need to be performed in that order.

[Select]

[03 - Brake Electronics]

[Security Access - 16]

Enter 40168, to enable the basic setting.

[Do it!]

[Basic Settings - 04]

Group 025

[Go!]

Calibration Input Values will be displayed.

Activate the Basic Setting.

[ON/OFF/Next]

- The control module will display the required pressure range in brackets.

- If Imp. VL [116/129] >000< Press Pedal 005 is displayed, press the pedal until the actual reading is within 116 ~ 129 and maintain that pressure until [000/000] is shown.

- Release pedal and wait until the next requested pressure set is shown.

- Repeat the procedure until No Valv [000/000]>000< Calibrated is shown.

De-Activate the Basic Setting.

[ON/OFF/Next]

Proceed to Basic Setting for Hydraulic Unit Disconnecting Valves

Note: if the following Basic Setting group is not available after the Intake Valves were adapted it may be necessary to end the diagnostic session with VCDS, shut the engine off and remove the key for a few seconds. Re-start the vehicle and proceed with the Disconnecting Valve procedure.

Basic Setting for Hydraulic Unit Disconnecting Valves

[Security Access - 16]

Enter 40168, to enable the basic setting.

[Do it!]

[Basic Settings - 04]

Group 026

[Go!]

Calibration MCI Values will be displayed.

Activate the Basic Setting.

[ON/OFF/Next]

- The control module will display the required pressure range in brackets.

- If MCI pri [096/103] >000< Press Pedal 005 is displayed, press the pedal until the actual reading is within 096 ~ 103 and maintain that pressure until [000/000] is shown.

- Release pedal and wait until the next requested pressure set is shown.

- Repeat the procedure until No Valv [000/000] >000< Calibrated is shown.

De-Activate the Basic Setting.

[ON/OFF/Next]

Video Link

http://www.youtube.com/watch?v=u8s1dwW9HwY

Replacement

After Replacing this Control Module these Steps have to be performed:

- Code Brake Electronics (J104) Control Module

- Basic Setting for Steering Angle Sensor (G85)

- Basic Setting for Lateral Acceleration Sensor (G200)

- Basic Setting for Brake Pressure Sensor 1 (G201)

- Basic Setting for Longitudinal Acceleration Sensor (G202)

If the (old) Hydraulics Unit is installed with a new or used ABS module these additional steps may need to be performed. This is only necessary when 00003 - Control Module: No or Incorrect Basic Setting / Adaptation is present.